Condenser Descaler

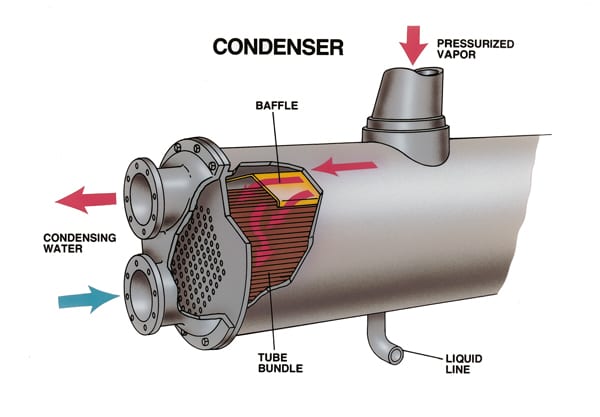

Condenser cleaning is made easy with RYDLYME Biodegradable Descaler. RYDLYME is simply circulated through the condenser removing mineral and scale build-up in a safe and timely manner.

Condensers and cooling towers require descaling maintenance due to the harsh mineral deposits such as calcium, lime, mud, and rust that rob heat transfer efficiency. For instance, most major manufacturers of condenser equipment generally design condensers to operate with a maximum “thermal resistance” or “fouling factor” of 0.0005 inches of buildup. As a result, with only 0.0360 inches (about 1/32”) of deposit corresponds to an increase in energy costs of over 30%! Now ask yourself, “Can I afford not to do a RYDLYME descaler cleaning on the condenser”?

Evaporative Condenser Cleaning

When water scale is deposited on the heat transfer surfaces of an evaporative condenser, the cooling water from the spray heads cannot efficiently condense the refrigerant gas in the coils. As a result, inadequate cooling, overworked machinery, and expensive operation is incurred. This is when RYDLYME condenser descaler is the perfect tool to remove the deposits.

To remove these deposits simply turn off the water supply, slowly add the recommended quantity of RYDLYME to the reservoir, turn on the circulating pump of the unit and circulate RYDLYME through the headers and spray nozzles. This will allow the RYDLYME to make contact with the heavy deposits of water scale surrounding the coils and dissolve these deposits into a solution, like sugar in coffee. After just a few hours, drain to normal plant sewer, water flush, and return the unit back to efficient operation! Watch this video of RYDLYME cleaning an evaporative condenser!

Shell & Tube Condenser Cleaning

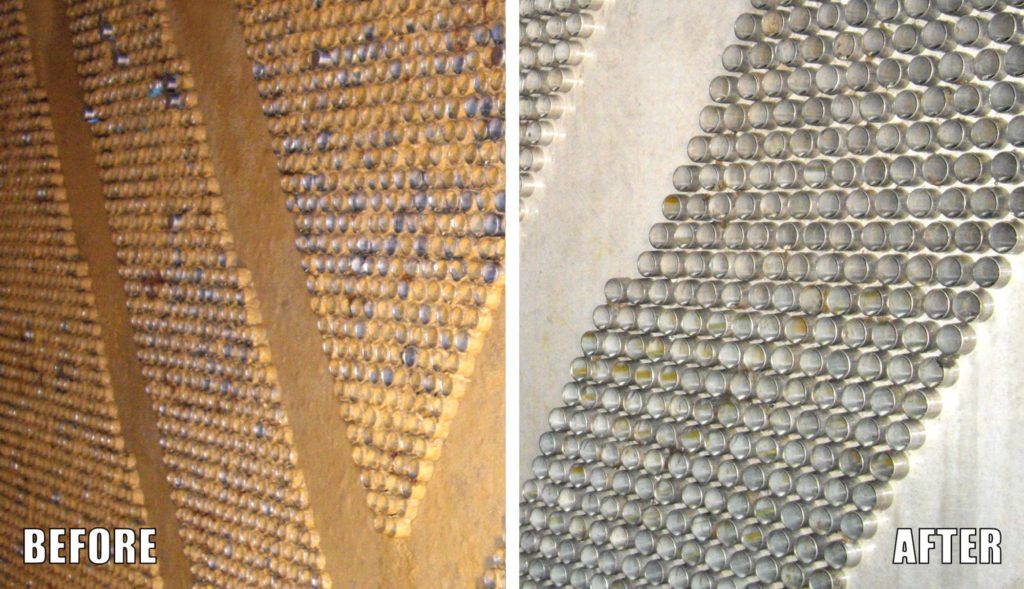

Water scale deposits in the condenser coils cause the compressor to kick out on high head pressure and lower the cooling capacity of the unit. To remove these insulating water scale, lime, mud, and rust deposits formed on the inside of the shell & tube condensers, simply circulate RYDLYME in through the water supply and out through the water return.

Circulate for the prescribed time or until the condenser is clean, flush with water, replace zinc or magnesium anodes, and return your equipment back to service, all within one eight-hour shift!

Absorption Unit Cleaning

Water scale, lime, mud, and rust deposits that accumulate on the waterside of absorbers and condensers materially affect the operation and efficiency of any absorption-type air conditioning unit.

The presence of these mineral deposits, along with lithium bromide or lithium molybdate, can usually be ascertained by the temperature readings of the inlet and outlet water to the absorber and condenser, the skin and gas temperatures, as well as the generator temperatures. When these temperatures fail to stay within an efficient operating range, the accumulated deposits should be removed with RYDLYME.

Water-formed deposits build up in absorbers and condensers at a rate dependent upon the hardness of the cooling water. The harder the water, the faster the deposits accumulate! Furthermore, a unit that has never been cleaned will require more RYDLYME that a unit receiving periodic or annual cleaning and proper maintenance.

The entire cooling water circuit, including the absorber, condenser, and piping can be cleaned while the unit is in operation. This attribute is especially important when humidity and temperature control are necessary to keep the plant at optimal operation.

RYDLYME FEATURES:

- Biodegradable

- Dissolves 2.2 lbs of scale per gallon of RYDLYME

- NSF/ANSI 60 certified

- Non-corrosive and safe for personnel

Condenser Descaler Case Studies

Significantly reduced heat transfer in the tubes of their main condenser due to heavy scale buildup resulting in reduced overall power plant efficiency.

Stubborn mineral deposits remaining in stainless steel tubes after prior shutdown’s mechanical cleaning.