Degreasing & Workplace Safety

Keeping things clean = safe workplace

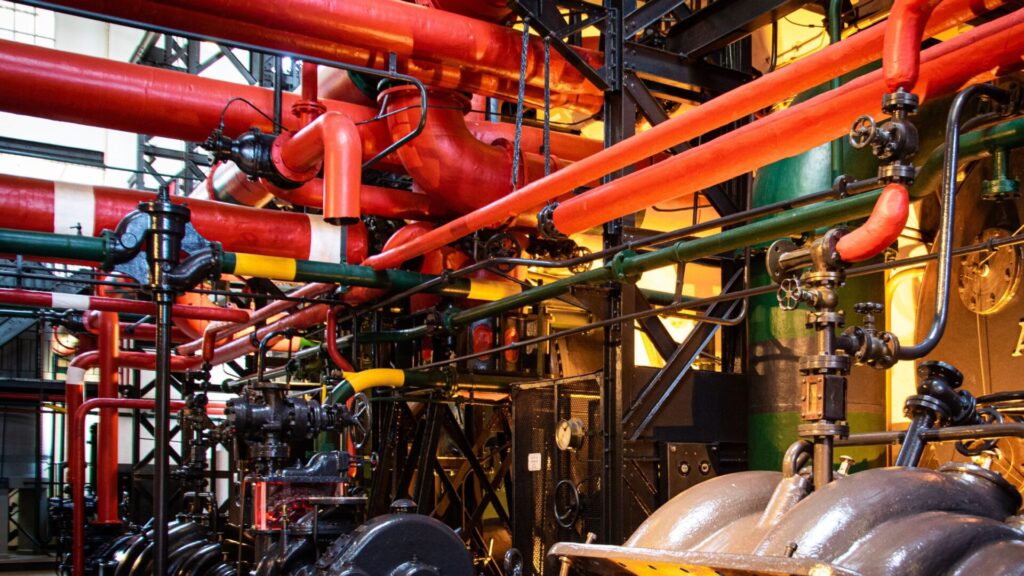

Degreasing equipment at any industrial facility is extremely important. Not just from a performance perspective–regular degreasing can help promote safety and avoid hazards & equipment malfunctions that may put workers at risk.

Degreasing improves safety at industrial facilities in a few different ways.

Reducing Slip Hazards

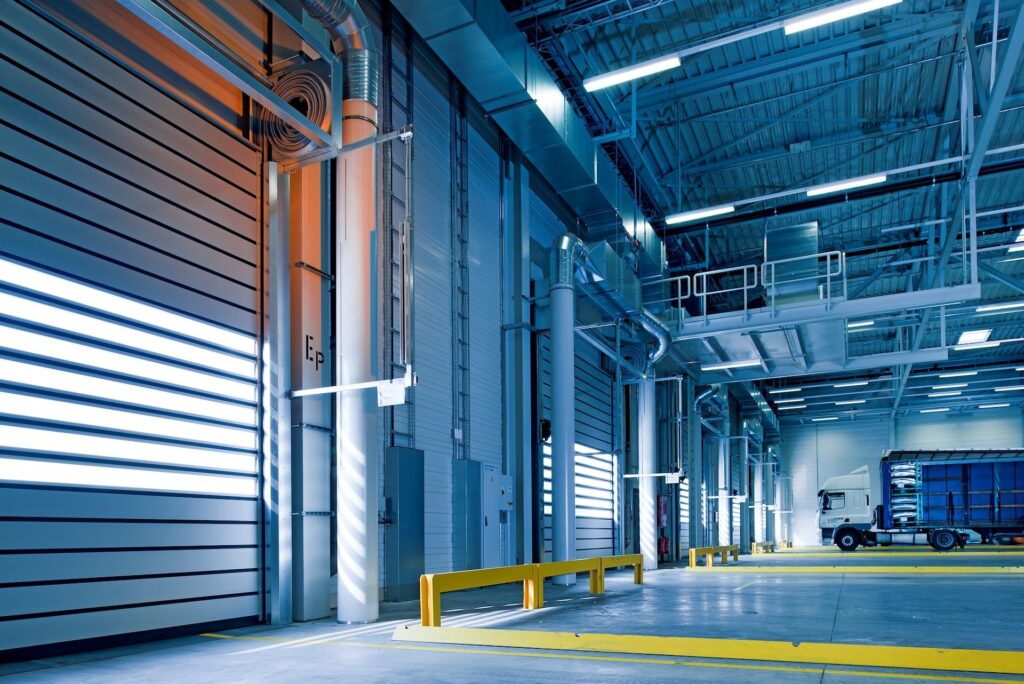

Grease and oil residues on floors, equipment, and machinery surfaces create slippery conditions, increasing the risk of slips, trips, and falls. Degreasing removes these residues, mitigating slip hazards and enhancing workplace safety.

Preventing Fire Hazards

Grease and oil buildup on machinery components can create fire hazards, especially in areas with high temperatures or sparks. Degreasing helps eliminate flammable residues, reducing the risk of fire incidents and ensuring a safer working environment.

Preventing Dangerous Equipment Malfunctions

Grease and oil accumulation can impair equipment performance, leading to malfunctions or breakdowns that may result in accidents, injuries, or damage to machinery and surrounding infrastructure.

Mitigate Health Risks

In addition to physical safety hazards, exposure to grease, oil, and other contaminants can pose health risks, such as skin irritation, respiratory problems, or long-term health effects from exposure to toxic substances.

There are two areas to keep in mind when thinking about degreasing & mitigating health risks. These areas are always important to keep an eye on as they lead to many easily preventable accidents and situations.

Poor Housekeeping

Inadequate housekeeping practices, such as failing to clean up spills promptly or neglecting regular floor maintenance, can allow grease and oil residues to accumulate over time, exacerbating the problem.

Environmental Factors

Environmental conditions such as temperature fluctuations, humidity levels, or exposure to outdoor elements can affect the viscosity and behavior of greases and oils, potentially leading to spills or leaks.

Enhancing Equipment Performance

Grease and oil accumulation on equipment can impair performance and functionality, leading to malfunctions or breakdowns that pose safety risks. Degreasing helps maintain equipment in optimal condition, reducing the likelihood of accidents caused by equipment failure.

Improving Visibility and Communication

Clean surfaces and equipment improve visibility and communication in industrial facilities. Degreasing removes contaminants that may obstruct signage, labels, or safety instructions, making it easier for workers to identify hazards and follow safety protocols.

Regulatory Compliance

Many regulatory standards and occupational safety guidelines require industrial facilities to maintain clean and safe working environments. Regular degreasing helps facilities comply with these regulations, avoiding penalties and ensuring the well-being of employees.

RYDLYME The World’s Leading Biodegradable Descaler

For more than 80 years, RYDLYME has been the most trusted brand for removing scale from many parts of data centers–boilers, cooling towers, heat exchangers, condensers, chillers, and so much more. If you have further questions pertaining to the effectiveness of “The World’s Leading Biodegradable Descaler,” RYDLYME , please feel free to contact our main office.