Green Liquor Descaling with RYDLYME

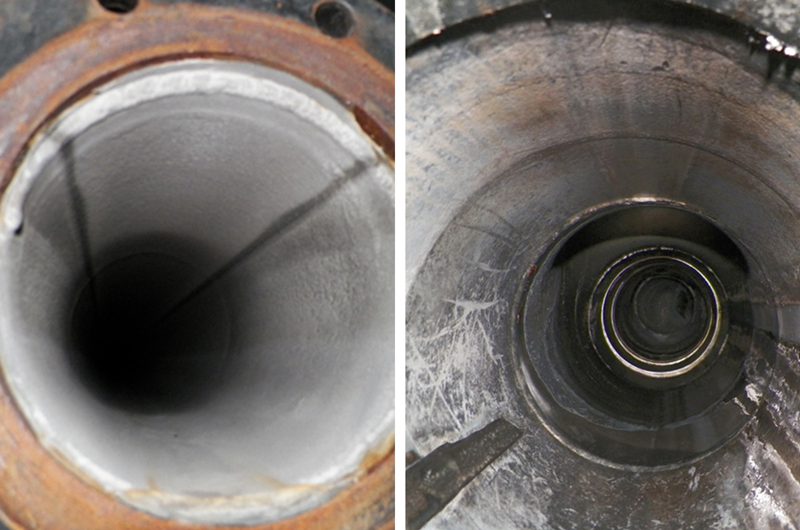

RYDLYME is the perfect green liquor descaler to circulate and remove mineral deposits from green liquor line systems in your pulp and paper mill! Simply circulate RYDLYME through the green liquor line system, dissolving mineral and scale build-up in a safe and timely manner.

RYDLYME Biodegradable Descaler is used to safely and efficiently dissolve tough mineral deposits such as water scale, limescale, calcium, and rust from boilers, chillers, cooling towers, condensers, heat exchangers, struvite, vacuum pumps, and more!

RYDLYME green liquor descaler is the ONLY product of its kind that is truly non-toxic and non-corrosive! Unlike other chemical descalers and traditional harsh acids, RYDLYME descaler can be safely handled by personnel (you can even hold it in your hand without injury!) and there are NO transportation or handling restrictions! It can be safely disposed of in normal plant sewers, even in the case of an accidental spill at the full concentration!

RYDLYME green liquor descaler is certified by an EPA-approved testing laboratory as a fully biodegradable and environmentally friendly chemical, even at 100% concentration WITHOUT neutralization! While other chemical descalers claim to be biodegradable, it does not equate to overall safety. In fact, some of them are classified as hazardous chemicals and have special handling requirements.

Check out our YouTube Channel or click here for videos! Check out our industrial descaling systems so you can circulate RYDLYME quickly, easily and safely!

Green Liquor Descaler Procedure Using RYDLYME

- Ascertain the maximum pump capacity in GPM or flow rate and volume through the system lines. Visually inspect the scatter sprayers for cleanliness and flow distribution.

- Drain and thoroughly flush the system to be cleaned, including both 4″ lines and the recovery tank. This is imperative, as the green liquor will rapidly expend the RYDLYME solution.

- Isolate the system by closing the section of the 3-way valve leading to the clarifiers, and the valve going to the overflow tank, along with any other valves that are necessary.

- Fill the system with water to a level 4″ above the lower level intake lines within the recovery tank. This should be a depth of 24″ from the base of the tank.

- Before adding the RYDLYME material to the system, test the circulation to confirm that the system is isolated. This will prevent “losing” any RYDLYME into areas that are not intended for this cleaning.

- Begin pumping the RYDLYME into the recovery tank a portion at a time and turning on the transfer pumps at each interval for approximately 20 minutes per interval. (i.e. If using l 000 gallons to clean the system add 330 gallons at a time, then circulate for 20 minutes)

- Circulate the concentration for 5 hours, taking solution samples every 2 hours to check for the effectiveness of the solution.

- Upon completion of the circulation, the solution may be flushed to normal sewers, as RYDLYME is 100% biodegradable. Flush the system thoroughly with water.

- The system may now be placed back in service without any need for neutralization or pacification.