Scale & Descalers: What to Know

Many common industrial cleaning suppliers are labeled descalers. This may confuse some people as it sounds like a specific application that only deals with ‘scales.’ This is not the case–descalers handle all sorts of blockages, deposits, and buildups typically found in industrial settings.

There are a few common general questions when it comes to scale and descalers. These questions deal with definitions and the applications of descalers. Let’s take a look.

What is Scale?

In general, scale refers to a thin, hard layer or coating that forms on the surface of an object due to the buildup of various materials or substances over time. The term can be used in a variety of contexts including industrial manufacturing, processing, refining, and machinery (among others).

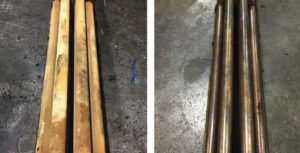

Scale Build up in Various Equipment

What is Scale Buildup?

Scale buildup refers to the accumulation of mineral deposits on surfaces such as pipes, faucets, and appliances that come into contact with hard water. Hard water is water that contains high levels of dissolved minerals, such as calcium and magnesium.

When hard water flows through pipes or comes into contact with surfaces, the minerals can gradually build up and form a hard, crusty layer, known as scale. Scale buildup can clog pipes and reduce water flow, and can also damage appliances such as dishwashers, washing machines, and coffee makers by reducing their efficiency and lifespan.

Scale buildup can be particularly problematic in areas with hard water, and can be a common issue in homes and buildings that use well water or municipal water supplies that have high levels of minerals.

To prevent scale buildup, it is recommended to use a water softener, which removes the minerals from the water before it enters the plumbing system. Regular cleaning of surfaces and appliances that come into contact with hard water can also help prevent scale buildup.

What is a Descaler?

An industrial descaler is a chemical product used to remove mineral scale buildup from industrial equipment and machinery that come into contact with hard water. The buildup of mineral scale can reduce the efficiency of equipment, leading to increased energy costs, reduced throughput, and even equipment failure.

Industrial descalers are formulated to dissolve mineral scale without damaging the underlying equipment. They are typically used in a variety of industries, such as power generation, oil and gas, food and beverage processing, and manufacturing.

The specific type of industrial descaler used depends on the type and severity of the scale buildup, as well as the type of equipment being cleaned. Some descalers are formulated for specific applications, such as cleaning heat exchangers, boilers, or cooling towers.

How do Descalers Work?

Industrial descalers work by dissolving and removing mineral scale buildup from equipment and machinery in industrial settings. The specific mechanism of action depends on the type of descaler being used, as well as the type of mineral scale being removed.

In general, industrial descalers contain chemicals that react with the mineral scale, breaking down its chemical structure and causing it to dissolve. This chemical reaction can generate heat, so it is important to use an appropriate descaler for the specific type of equipment and mineral buildup and to follow the manufacturer’s instructions carefully to avoid damage to the equipment.

Some industrial descalers are formulated to work on specific types of mineral scales, such as calcium carbonate or iron oxide. Others may be more general-purpose, designed to work on a range of mineral buildup. The effectiveness of a descaler depends on factors such as the strength and concentration of the product, the duration of contact with the mineral buildup, and the temperature and pressure of the equipment being cleaned.

Descalers may or may not be biodegradable. Biodegradable descalers can be easily disposed of in most drainage systems. Non-biodegradable descalers have special disposal requirements.