The Hidden Costs of Neglecting Heat Exchanger Cleaning

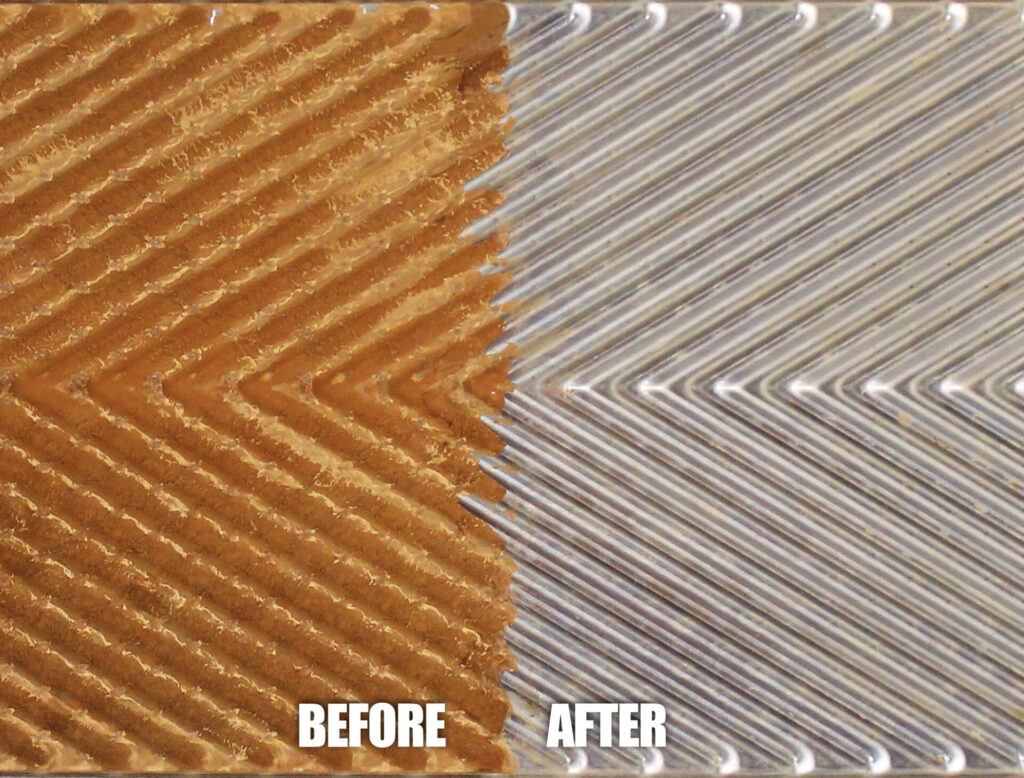

Water scale is corrosive to equipment – descale it!

The hidden costs of neglecting heat exchanger cleaning can be significant and far-reaching. From increased energy consumption and reduced efficiency to higher maintenance costs and potential environmental violations, the consequences of overlooking regular cleaning are often much more expensive than the investment in routine upkeep.

For businesses that rely on heat exchangers to maintain optimal performance, it is critical to adopt a proactive maintenance strategy that includes regular cleaning and inspection. By doing so, companies can ensure that their systems run efficiently, reduce the risk of costly downtime, and extend the lifespan of their equipment. Let’s take a closer look.

Reduced Efficiency and Increased Energy Costs

The most immediate consequence of a dirty or clogged heat exchanger is reduced efficiency. When the surfaces of the heat exchanger become coated with scale, fouling, or debris, it obstructs the heat transfer process.

As a result, the system must work harder to achieve the same output, leading to an increase in energy consumption. Over time, this inefficiency adds up, raising energy costs and significantly affecting the bottom line. In industries where energy costs account for a substantial portion of operational expenses, these increased costs can be particularly impactful.

Decreased Equipment Lifespan

Heat exchangers are designed to operate within specific performance parameters. When they are not cleaned regularly, contaminants accumulate and cause blockages or corrosion, placing undue stress on the components.

This not only reduces the heat exchanger’s ability to perform efficiently but also accelerates wear and tear. The resulting strain can lead to premature failures, costly repairs, or even the need for complete replacements. In the long run, neglecting proper maintenance can reduce the lifespan of heat exchangers, requiring more frequent replacements and significantly increasing capital expenditures.

Risk of Unplanned Downtime

A dirty heat exchanger can fail unexpectedly, leading to unplanned downtime. Unscheduled maintenance or repairs can halt production processes, disrupt operations, and cause delays. In some industries, such interruptions may lead to missed deadlines, loss of business, and even fines for non-compliance with operational standards.

Unplanned downtime is especially costly because it often involves urgent repairs, rushed labor, and additional costs to get operations back on track. Regular cleaning can prevent such scenarios, ensuring that the heat exchanger functions optimally and minimizing the risk of sudden failures.

Increased Maintenance and Repair Costs

As mentioned earlier, neglecting heat exchanger cleaning can lead to severe damage over time. When fouling or scaling becomes too extensive, the damage to internal components may be irreversible. This necessitates costly repairs or the replacement of entire systems. Moreover, cleaning a severely clogged heat exchanger is a far more complicated and time-consuming process compared to routine maintenance.

This escalation in the scope of repair work adds both labor and material costs. Routine cleaning, on the other hand, is a relatively low-cost preventative measure that can save significant sums in the long run.

Environmental Impact

Another often-overlooked consequence of neglecting heat exchanger maintenance is the environmental impact. Heat exchangers that are not operating efficiently release more energy into the environment, often in the form of excess heat or gases.

In industries where carbon emissions and energy consumption are tightly regulated, failing to maintain equipment could lead to violations of environmental standards, resulting in fines or legal consequences. Regular cleaning ensures that the heat exchanger operates efficiently and within regulatory limits, minimizing the environmental footprint of operations.

RYDLYME The World’s Leading Biodegradable Descaler

For more than 80 years, RYDLYME has been the most trusted brand for removing scale from many parts of data centers–boilers, cooling towers, heat exchangers, condensers, chillers, and so much more. If you have further questions pertaining to the effectiveness of “The World’s Leading Biodegradable Descaler,” RYDLYME , please feel free to contact our main office.