Heat exchangers are essential components in various industrial processes, and maintaining their efficiency is crucial for optimal operation. Over time, however, heat exchangers can experience fouling or scaling that can reduce performance.

Let’s check out the top signs that your heat exchanges is in need of chemical cleaning.

Let’s check out the top signs that your heat exchanges is in need of chemical cleaning.

Reduced Heat Transfer Efficiency

Significance: If the heat exchanger is struggling to maintain the desired temperature differential or operating at a lower-than-expected heat transfer rate, this indicates that fouling or scaling may be hindering its performance.

What to look for: Higher energy consumption, increased fluid temperatures, or extended processing times to achieve the desired output.

Increased Pressure Drop

Significance: A buildup of deposits inside the heat exchanger reduces the flow of fluids, leading to a higher resistance to flow (pressure drop). This can affect the overall performance of the system.

What to look for: If you notice that pressure readings have increased significantly compared to normal operation, it could be time for chemical cleaning.

Frequent or Unscheduled Maintenance

Significance: Frequent breakdowns or the need for more regular repairs are signs that the heat exchanger is not functioning optimally.

What to look for: If you are experiencing an increase in unscheduled maintenance or repair tasks, fouling may be compromising the heat exchanger’s function.

Decreased Flow Rates

Significance: Fouling or scaling inside the heat exchanger restricts fluid flow, which can cause reduced flow rates.

What to look for: If flow rates are significantly lower than expected, or if flow meters show that throughput has decreased, it might be due to internal build-up.

Unusual Noises

Significance: While the heat exchanger is in operation, unusual sounds such as gurgling or bubbling could be a sign that there is air or steam trapped due to restricted flow, caused by fouling or scaling.

What to look for: Uncommon noises that weren’t present during normal operations could indicate internal blockages or flow restrictions.

Temperature Fluctuations

Significance: When fouling builds up in the heat exchanger, it impairs heat transfer, causing uneven temperature distribution or difficulty maintaining the set temperature.

What to look for: Fluctuating outlet temperatures or an inability to maintain a stable operating temperature are indicators that heat transfer is being compromised.

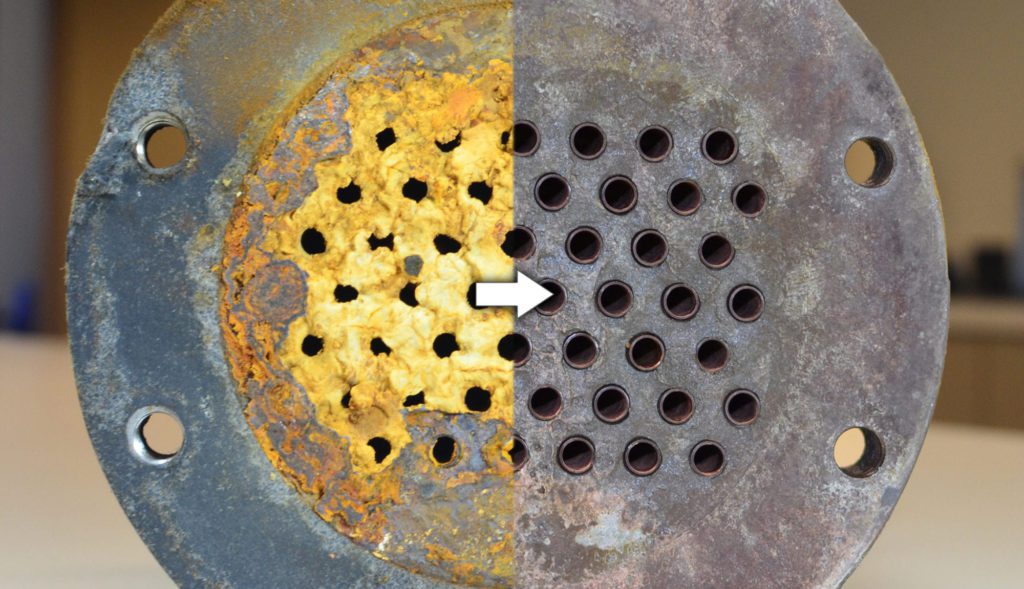

Corrosion or Leaks

Significance: The accumulation of deposits can cause uneven temperatures, leading to localized corrosion. If corrosion progresses without being addressed, it can lead to leaks.

What to look for: Visible corrosion, leaks, or signs of material degradation on heat exchanger surfaces suggest that cleaning is required to prevent further damage.

Reduced System Efficiency

Significance: When heat exchangers underperform due to fouling or scaling, the entire system becomes less efficient, leading to increased energy consumption and operating costs.

What to look for: An increase in operational costs, particularly energy bills, or a general decline in system performance, could be tied to reduced heat exchange efficiency.

Poor Output Quality

Significance: In industrial applications where precise temperature control is critical (e.g., chemical processes), fouling in the heat exchanger can lead to poor-quality output.

What to look for: If product quality or consistency is declining, especially in processes that rely on specific heat transfer conditions, it may be due to heat exchanger inefficiency.

Extended Recovery Time

Significance: If the heat exchanger is taking longer to return to its normal operating conditions after shutdown or reduced operation, this can indicate the need for cleaning.

What to look for: Slow recovery times when restarting the system or longer warm-up periods could point to fouling that is affecting performance.

RYDLYME The World’s Leading Biodegradable Descaler

For more than 80 years, RYDLYME has been the most trusted brand for removing scale from many parts of data centers–boilers, cooling towers, heat exchangers, condensers, chillers, and so much more. If you have further questions pertaining to the effectiveness of “The World’s Leading Biodegradable Descaler,” RYDLYME, please feel free to contact our main office.