Wastewater Pipe Cleaning

It may seem contradictory that wastewater pipes need cleaning. The truth, however, is that wastewater facilities and related sites need pipe cleaning more than most industrial outfits.

Wastewater processing facilities use piping networks to move wastewater from point A to point B. Any piping system will accumulate buildup from water over time, but wastewater facility piping is on another level. Buildups can happen faster and be more aggressive than they would be in a facility dealing with ‘clean’ water.

This is why it is so important to schedule regular maintenance and cleaning for any wastewater facility or processing plant.

Click here to view other videos or check out our YouTube page.

Wastewater Processing Pipe Buildups

Wastewater processing facilities can experience a lot of scale & other mineral build-ups over relatively short periods of time. Dirty water traveling through pipe systems will leave particles floating around wherever it is circulated.

The buildups left by the wastewater can, over time, effectively decrease the diameter of a pipe. This means decreased flow, which can lead to inefficiency and skyrocketing costs. Regular cleaning and maintenance, however, can prevent these buildups from getting to a point where they effect integral procedures.

Regular Pipe Cleaning Maintenance

Buildups of scale and other minerals are the main reason why pipes in industrial facilities need to be regularly cleaned. Aside from the reduced efficiency caused by accumulated build-ups in the pipes, neglected systems can end up costing a prohibitive amount of money to fix.

Making sure your pipe system has regularly scheduled maintenance should be at the top of your list when it comes to water facility maintenance. Unlike most industrial settings, water & wastewater facilities focus on the water (and don’t just use it in boiler, cooler, or other periphery systems).

Maintaining the pipes of a wastewater treatment plant or water facility in general is maintaining the plant itself.

Descaling Wastewater Pipes

Like most piping systems, wastewater facility piping can be effectively cleaned by using chemical descaling solutions. Descaling solutions are formulated to efficiently remove scale and other contaminants from piping and other surfaces.

Industrial descaling solutions are specially formulated to target the worst offenders when it comes to scale and contaminant buildup offenders. These descalers can be used on a large scale to remove build-ups and restore facilities to their optimal potential.

Cleaning Wastewater Pipes with RYDLYME

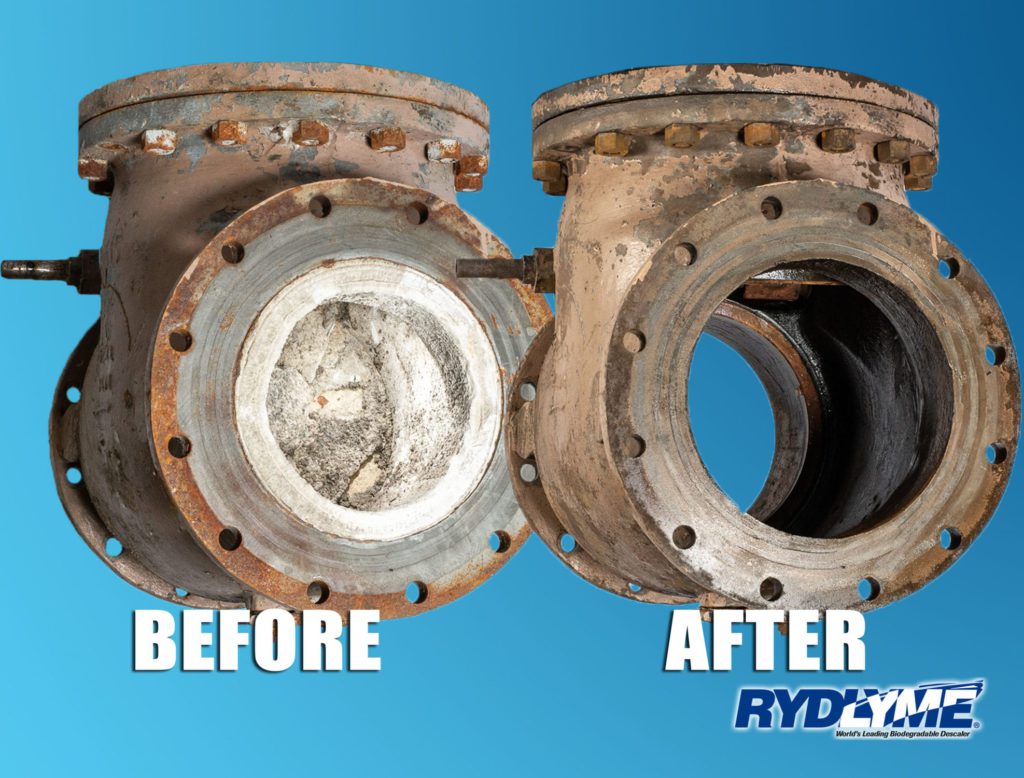

Check out this example of just how much dirty pipes can affect the performance of a wastewater facility:

A pharmaceutical developer’s wastewater system was experiencing flow issues caused by the collection of struvite scale deposits. The system consisted of over 1,000 feet of 8” pipe containing 2,640 gallons along with transfer pumps which normally provide flow rates of 300 gallons per minute. However, the struvite had become so severe that the pumps were restricted to just 60 gpm or 20% of their design capabilities.

A circulation loop was established to pump 2,640 gallons of RYDLYME through the system and dissolve the struvite deposits. Given just 8 hours at 100% concentration, the RYDLYME had completed the cleaning and was flushed from the system. The pumps were turned on and immediately achieved 300 GPM!

The facility has already updated its preventative maintenance program and implemented semi-annual RYDLYME cleanings to avoid this problem in the future.

RYDLYME The World’s Leading Biodegradable Descaler

For more than 80 years, RYDLYME has been the most trusted brand for removing scale from boilers, cooling towers, heat exchangers, condensers, chillers, and so much more. If you have further questions pertaining to the effectiveness of “The World’s Leading Biodegradable Descaler,” RYDLYME , please feel free to contact our main office.