Oil & Gas Descaler

If you’re looking to optimize the performance of cooling towers, heat exchangers, vacuum pumps, jacket reactors, or any other water-operated equipment plagued by water scale buildup, you’ve come to the right place. Discover how RYDLYME can help you maximize efficiency and minimize downtime in your operations.

Water scale, also known as mineral scale or calcium scale, poses a significant challenge in the oil and gas industry. The accumulation of mineral deposits, such as calcium, within equipment like cooling towers and heat exchangers can lead to a myriad of problems:

1. Reduced Efficiency: Scale buildup insulates heat transfer surfaces, reducing the efficiency of equipment and increasing energy consumption.

2. Maintenance Headaches: Scaling leads to increased maintenance requirements, downtime, and associated costs.

3. Corrosion Risk: Scale can create corrosive environments within equipment, leading to costly repairs or replacements.

4. Safety Concerns: Reduced efficiency can affect the overall safety of the operation, potentially leading to accidents or failures.

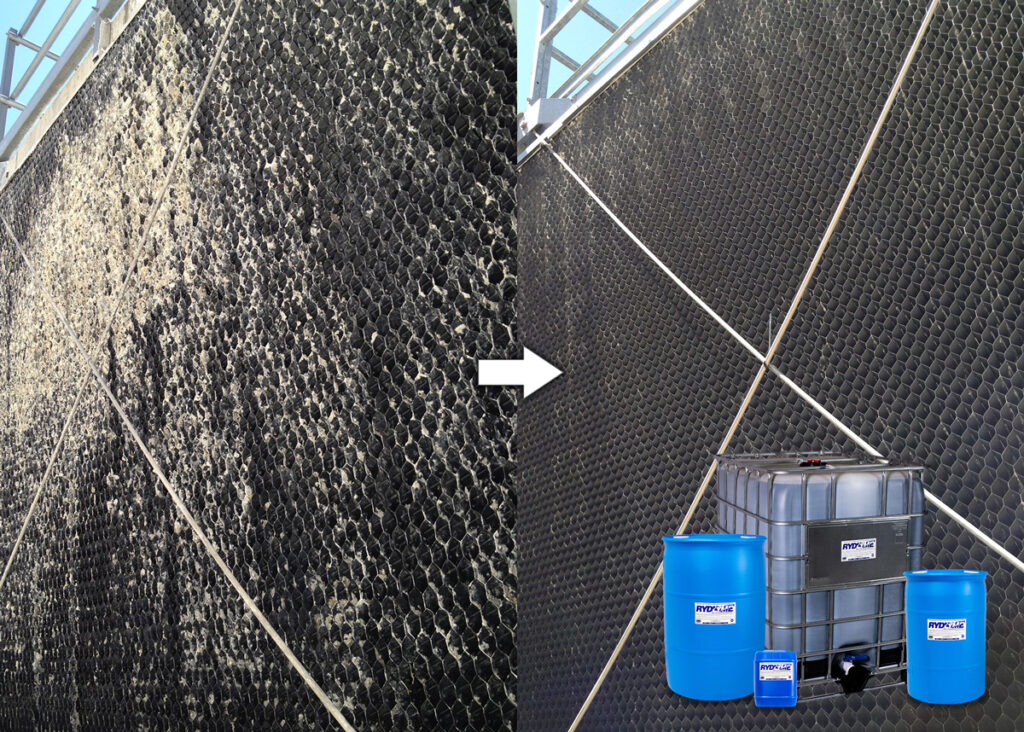

RYDLYME Biodegradable Descaler is used to safely and efficiently dissolve tough mineral deposits such as water scale, limescale, calcium, and rust from boilers, chillers, cooling towers, condensers, heat exchangers, struvite, and more!

Recommended by the U.S. Navy and countless OEMs, RYDLYME descaling chemical is NSF-registered for use in various industries and applications including beverage, pharmaceutical, bottling, and food processing plants, as well as NSF/ANSI standard 60-certified as a cleaner for potable water systems and manufactured in an ISO 9001 Certified Facility.

Cooling towers play a critical role in maintaining optimal temperatures in industrial processes. RYDLYME descaler effectively removes scale buildup, ensuring your cooling towers operate efficiently and reliably.

Efficient heat exchange is essential in various oil and gas processes. RYDLYME can rejuvenate heat exchangers, improving heat transfer and reducing energy consumption.

Scale in vacuum pumps can impair their performance and increase energy costs. RYDLYME removes scale, restoring vacuum pumps to their peak efficiency.

Jacketed reactors are susceptible to scale accumulation, affecting temperature control. RYDLYME descaling ensures consistent and efficient reactions.

Whether it’s pipes, valves, or any water-operated equipment, RYDLYME can be used to tackle scale buildup, ensuring smooth and efficient operation across your facility.

In the oil and gas industry, minimizing downtime and optimizing efficiency are paramount. RYDLYME descaler offers a cost-effective, biodegradable solution to the pervasive problem of water scale. Don’t let scale buildup impede your operations and increase your costs—choose RYDLYME for superior descaling performance.

Contact us today to learn more about how RYDLYME can revolutionize your oil and gas operations by enhancing equipment efficiency and prolonging the lifespan of your critical assets. Let us help you scale down on scale-related problems and scale up your productivity.