Product Description

RYDLYME Biodegradable Descaler is used to safely and efficiently dissolve tough mineral deposits such as water scale, limescale, calcium, and rust from the water side of industrial equipment!

Recommended by the U.S. Navy and countless OEMs, RYDLYME descaling chemical is NSF-registered for use in various industries and applications including beverage, pharmaceutical, bottling, and food processing plants, as well as NSF/ANSI/CAN standard 60-certified as a cleaner for potable water systems and manufactured in an ISO 9001 Certified Facility.

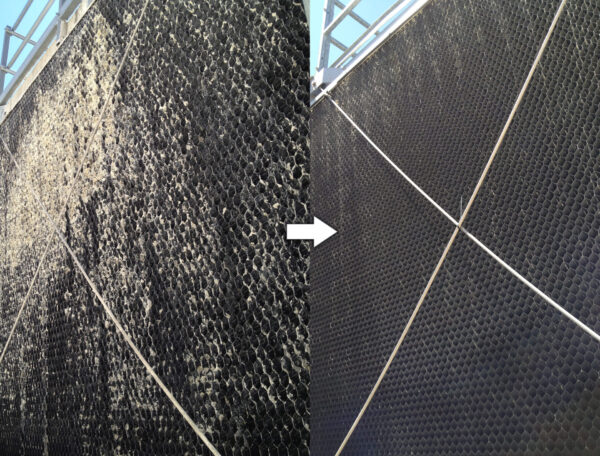

Why use a cooling tower cleaning kit?

A cooling tower cleaning kit utilizing RYDLYME biodegradable descaler and a 75LDP with included brass spray nozzle saves time, money and returns cooling towers’ or evaporative condensers’ operating temperatures back to normal by dissolving calcium and other harsh water-formed mineral deposits.

How often is a cooling tower cleaning kit used?

The cooling tower cleaning kit is used to transfer RYDLYME into the cooling tower or evaporative condenser basin. While RYDLYME is circulating through the system, the transfer pump tube is added to the basin. Using the supplied brass nozzle, spray the outside of the cooling tower fill back into the basin or spray the tubes on an evaporative condenser with diluted RYDLYME to dissolve hard to reach areas.

An annual RYDLYME cleaning of a cooling tower/evaporative condenser will dissolve and remove the calcium, magnesium, rust, and other deposits into the solution without harming the components within your cooling tower system. Another benefit to cleaning cooling towers or evaporative condensers with RYDLYME is that the non-corrosive descaler is safe for personnel who perform the cleaning and can be disposed of down an ordinary drain.

Our descaler is the universal product of choice to clean cooling towers or evaporative condensers. Cleaning the cooling tower on a regular basis will improve the system’s technical and economic performance.

Our industrial descaling systems are strategically built to circulate RYDLYME throughout the cooling tower or evaporative condenser to dissolve these efficiency-robbing mineral deposits. View more videos on our YouTube page.

What is included in a cooling tower cleaning kit?

- A recommended quantity of RYDLYME Biodegradable Descaler

- A 75LDP to transfer RYDLYME into the basin and a brass spray nozzle to focus on hard to reach areas while RYDLYME is circulating

- Knowledge and expertise in cleaning your cooling tower or evaporative condenser

FAQ

Q: If RYDLYME contains HCl (hydrochloric acid), how can it be safe on my skin?

A: Though the active ingredient is HCl, there is less than 10% of the acid, and it’s only one element of the overall formula. Couple this with the special way it’s blended, and you have a nice balance of safety, biodegradability, and effectiveness. That’s what makes RYDLYME so unique and why similar products fall short.

Q: Since RYDLYME contains HCl, should I be concerned about corrosion on stainless steel, such as hydrogen embrittlement?

A: There is no need to worry about hydrogen embrittlement. When used properly, RYDLYME’s unique formula will not corrode stainless steel or virtually any metal or material associated with water-based equipment.

Q: Does RYDLYME need to be used at a 100% concentration or should it be diluted?

A: RYDLYME is a powerful and concentrated descaler. Depending on the application, severity of buildup, and available time, RYDLYME can be diluted down to 25% while still maintaining its full effectiveness. To find out the proper dilution ratio for your specific application, please Contact Us.

Q: How long will it take for RYDLYME to dissolve the buildup in my equipment/system?

A: Though most cleaning applications can be completed within a few hours, actual cleaning times depend on a variety of factors, including the size of the equipment/system, the severity of buildup, and the method of circulation. Contact Us for an evaluation of your scaling problem and equipment to determine the proper amount of RYDLYME and the circulation method that should be used.

Q: How can I tell when RYDLYME is finished cleaning my system?

A: In addition to experiencing improved performance, you can perform either a calcium carbonate spot test or a pH test. These tests are explained in detail in our Testing the Effectiveness of RYDLYME information sheet.

Q: In regards to your seashell demo online and in-person, I’ve seen other products doing the same thing with dissolving the shell in their chemical. What’s so special about RYDLYME?

A: Look at those videos again. Are they dropping the shell into a container or the palm of their hand? As previously mentioned, the safety element of RYDLYME is unmatched. You can put it in your hand or equipment without harm. Also, have an added piece of mind that you, your personnel, and the facility are safe in the unfortunate event of an accident, such as a spill or equipment failure.

Q: Is RYDLYME safe in food processing or drinking water applications?

A: Yes! RYDLYME is NSF/ANSI Standard 60-certified, meaning it is approved as a safe drinking water treatment chemical. It is also NSF-registered for use in industries such as beverage, pharmaceutical, bottling, and food processing plants.