The industry’s most effective struvite remover. NSF certified, biodegradable solution that safely dissolves struvite deposits in pipes, pumps, and equipment without damage.

Professional Struvite Removal with RYDLYME Descaler

NSF/ANSI 60/CAN Certified

No Equipment Damage

Biodegradable Formula

Fast Acting

Why Choose RYDLYME to Remove Struvite?

Dissolves Struvite Safely

Removes stubborn struvite deposits without damaging equipment

NSF Certified

Safe for use in drinking water systems and food processing facilities

Cost Effective

Reduces maintenance costs and extends equipment life

Why RYDLYME is the Best Struvite Remover

RYDLYME struvite removal solution combines safety, effectiveness, and environmental responsibility to deliver superior results in removing stubborn struvite deposits.

How RYDLYME Struvite Remover Works

Our proven 4-step process ensures effective struvite removal while protecting your valuable equipment.

Need help with struvite removal?

Our technical experts can help determine the best approach for your specific struvite challenge.

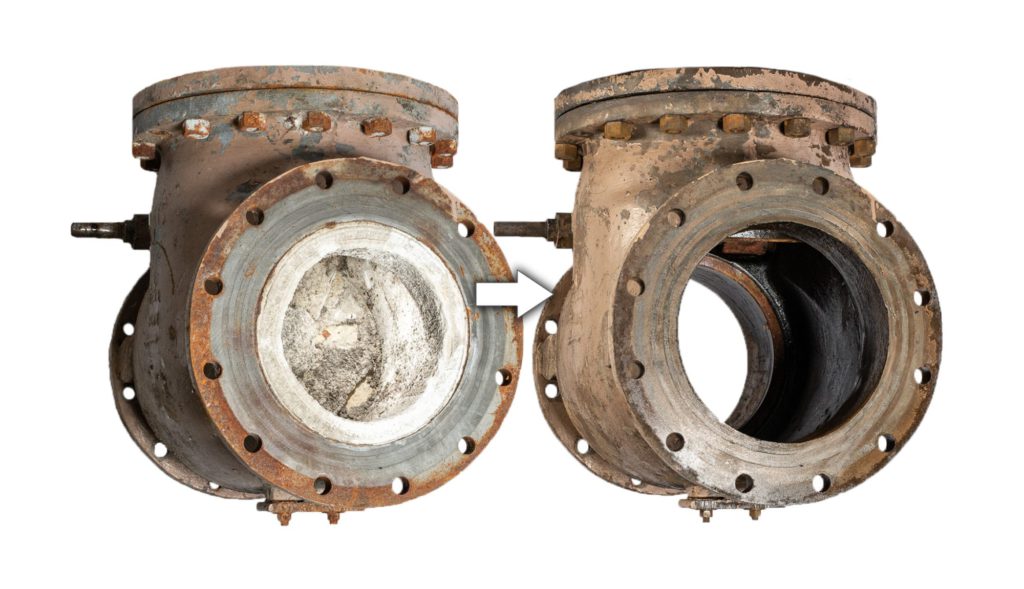

RYDLYME Struvite Remover in Action

RYDLYME struvite remover is effective and safe. See the evidence in case studies and videos.

WWTP Pipeline Descaling

A Canadian wastewater treatment plant (WWTP) was facing severe flow issues in a 1.5-mile-long underground pipeline.

Centrifuge Cleaning

A Midwest WWTP experiencing struvite buildup on their centrifuge systems used RYDLYME descaler as a solution to remove struvite.

Heat Exchanger Struvite Removal

A Midwest wastewater treatment plant was experiencing struvite buildup in their heat exchanger as well as the 62′ of 6″ piping.

Lift Station Struvite Removal

A midwestern wastewater facility was severely hindered by struvite blockage within one of their lift stations. RYDLYME dissolved all of the struvite!

Frequently Asked Questions About Struvite Removal

Get answers to common questions about RYDLYME struvite remover and struvite removal processes.

Struvite is a crystalline mineral deposit (magnesium ammonium phosphate) that forms in wastewater systems, pipes, and equipment. It reduces flow capacity, damages pumps, clogs pipes, and increases maintenance costs. Regular struvite removal is essential for maintaining system efficiency.

RYDLYME is NSF certified, biodegradable, and safe for all common materials. Unlike harsh acids or caustics, RYDLYME dissolves struvite without damaging equipment. It’s also safer for workers and the environment while being more effective than traditional struvite removal methods.

Yes, RYDLYME is NSF/ANSI 60 certified for use in drinking water systems. It’s safe for potable water applications when used according to guidelines and properly rinsed after treatment.

Treatment time varies based on the severity of struvite buildup, but typically ranges from 2-8 hours. Light deposits may dissolve in 2-4 hours, while heavy buildup may require 6-8 hours of contact time for complete removal.

For struvite removal, we typically recommend 50-100% RYDLYME concentration. The exact concentration depends on the severity of buildup and your specific application. Our technical team can help determine the optimal concentration for your needs.

The frequency depends on your system’s struvite formation rate. Some facilities benefit from monthly treatments, while others may need quarterly or annual cleaning. Regular preventive treatment is more cost-effective than waiting for severe buildup.

RYDLYME can be applied using existing system pumps for circulation, or by using an industrial descaling system manufactured by Apex Engineering Products. Circulation pumps help ensure even distribution and faster struvite dissolution.

Apex highly recommends that, prior to cleaning, you contact us for technical assistance in determining the best dilution and method for removing your struvite scale deposits. For more information on how to remove struvite, click here.

- Obtain struvite deposit for testing with RYDLYME to confirm adequate concentration to dissolve struvite (typically 50-100%). Note the severity of struvite build-up. Obtain the current water volume of the struvite infected system as well as the designed water volume.

- To set up a circulation, connect the circulating pump inlet to the vented container via a hose.

- Run another hose from the pump outlet to the lowest accessible point of the struvite-infected system.

- Run another hose from the highest accessible point of the struvite infected system back to the vented circulating container.

- Add the prescribed amount of RYDLYME to the circulating container and turn on the pump to begin dissolving the struvite. Add water to the solution until a complete circuit is obtained.

- Continue circulation for 6-12 hours depending on struvite severity and volume of the system. Hourly monitor the RYDLYME solution to determine the endpoint. If RYDLYME is neutralized prior to the prescribed circulating duration, then more RYDLYME should be added in order to remove the remaining struvite. (See “Testing the Effectiveness of RYDLYME”)

- Upon completion of the struvite cleaning, rinse the system with clean water to remove any insoluble materials that may have been released from the struvite deposit.

- Return the system to service.

- Biodegradable

- Dissolves 2.2 lbs of scale per gallon of RYDLYME

- NSF/ANSI 60 certified

- Non-hazardous and safe for personnel

RYDLYME Technical Specifications

Detailed technical information for engineers and facility managers planning struvite removal projects.

Product Specifications

Applications and Industries

pH Level:

1 – 3

Biodegradable:

Yes

Non-Hazardous:

Yes

NSF Certification:

NSF/ANSI 60/CAN Certified

Application Guidelines

Concentration:

50% – 100% for struvite removal

Temperature Range:

Room temperature

Contact Time:

2-12 hours depending on buildup

Primary Applications

- Wastewater treatment plants

- Municipal water systems

- Food processing facilities

- Rendering plants

- Pharmaceutical manufacturing

- Brewery and distillery operations

- Industrial cooling systems

- Heat exchangers and condensers

- Pumps and piping systems

Safety & Handling

Personal Protection:

Safety glasses, chemical-resistant gloves

Ventilation:

Use in well-ventilated areas

Storage:

Store in original container

Shelf life:

5 years when properly stored

Need Technical Assistance?

Our engineers can help you calculate the right concentration and application method for your struvite removal needs.