Mining Industry Descaler

If you’re looking to optimize the performance of heat exchangers, cooling towers, vacuum pumps, pumps, pipelines, boilers, or any other water-operated equipment plagued by water scale buildup, you’ve come to the right place. Discover how RYDLYME can help you maximize efficiency and minimize downtime in your operations.

Water scaling is a pervasive issue in the mining industry, affecting various equipment critical to mining operations. Scaling occurs when minerals and other impurities in water accumulate on surfaces, forming a hard, crystalline layer. This can lead to reduced efficiency, increased energy consumption, and the need for frequent maintenance. Several key pieces of equipment in the mining industry are particularly susceptible to scaling, including heat exchangers, cooling towers, vacuum pumps, pumps, and pipelines.

In mining operations, heat exchangers play a crucial role in maintaining optimal temperatures for various processes. However, when water with high mineral content is used in these systems, scaling can occur on the heat exchanger surfaces. This reduces heat transfer efficiency, leading to increased energy consumption and decreased overall system performance. Regular cleaning and descaling are necessary to ensure the smooth operation of heat exchangers.

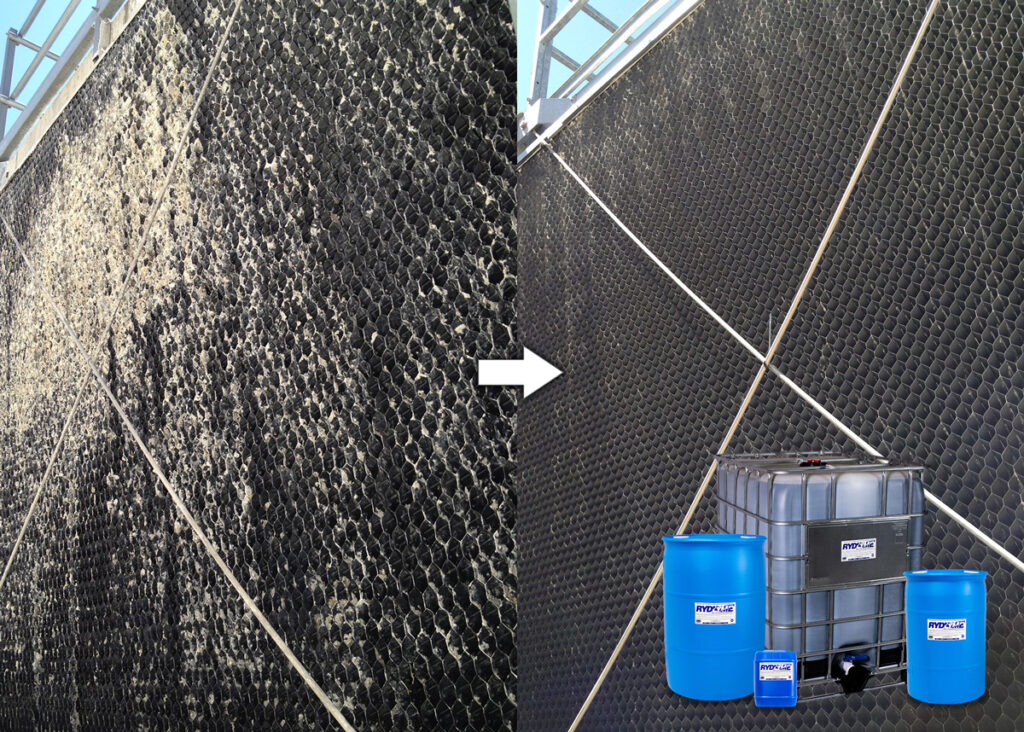

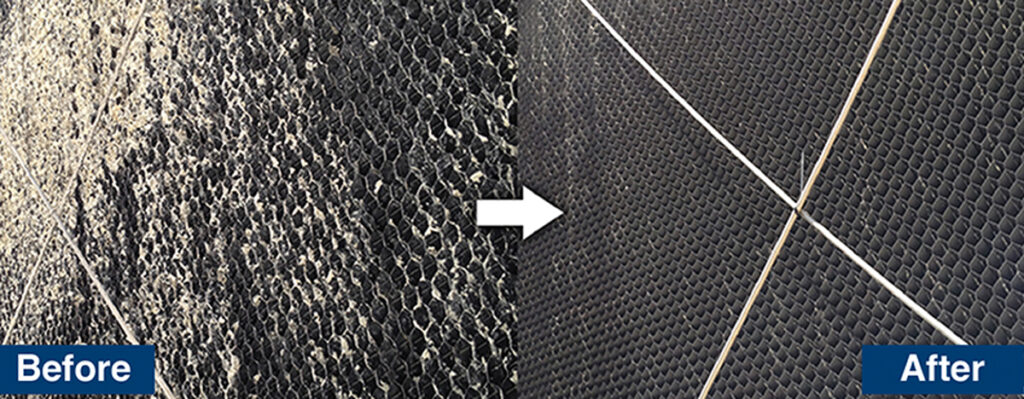

Cooling Towers

Cooling TowersCooling towers are employed to dissipate heat generated during mining processes. Scaling in cooling towers can impede the flow of water, reducing the tower’s cooling capacity. This can result in higher temperatures in critical equipment and a decline in operational efficiency. Additionally, scaling can lead to corrosion issues in the cooling system. Routine maintenance with RYDLYME are essential to mitigate scaling in cooling towers.

Vacuum Pumps

Vacuum PumpsVacuum pumps are used in various mining applications, such as material handling and processing. Scaling in vacuum pumps can lead to decreased pump performance, increased energy consumption, and a higher risk of mechanical failure. Regular inspection and cleaning are necessary to prevent scaling issues and maintain the efficiency of vacuum pump systems.

Pumps

PumpsScaling within pumps can cause reduced flow rates and increased energy consumption. It can also lead to cavitation, which can damage pump components. Proper inspection and regular maintenance with RYDLYME are crucial to preventing scaling in pumps and ensuring their reliability in mining operations.

Pipelines

PipelinesScaling in pipelines can result in reduced flow rates and increased pressure drop. Over time, this can lead to decreased efficiency and increased energy costs for transporting materials within the mining facility. Regular inspection, cleaning, and descaling with RYDLYME are necessary to combat scaling in pipelines.

Boilers

BoilersBoilers are commonly used in mining operations for steam generation. Scaling in boilers can reduce heat transfer efficiency, leading to increased fuel consumption. It can also result in uneven heat distribution and increased maintenance costs. Regular inspection and maintenance of the boiler are critical to maintaining the performance and reliability of boiler systems.

Water-Operated Equipment

Water-Operated EquipmentWhether it’s pipes, valves, or any water-operated equipment, RYDLYME can be used to tackle scale buildup, ensuring smooth and efficient operation across your facility.

In the mining industry, minimizing downtime and optimizing efficiency are paramount. RYDLYME descaler offers a cost-effective, biodegradable solution to the pervasive problem of water scale. Don’t let scale buildup impede your operations and increase your costs—choose RYDLYME for superior descaling performance.

Contact us today to learn more about how RYDLYME can revolutionize your mining operations by enhancing equipment efficiency and prolonging the lifespan of your critical assets. Let us help you scale down on scale-related problems and scale up your productivity.

RYDLYME Biodegradable Descaler is used to safely and efficiently dissolve tough mineral deposits such as water scale, limescale, calcium, and rust from boilers, chillers, cooling towers, condensers, heat exchangers, struvite, and more! View videos of RYDLYME in action here.

Recommended by the U.S. Navy and countless OEMs, RYDLYME descaling chemical is NSF-registered for use in various industries and applications including beverage, pharmaceutical, bottling, and food processing plants, as well as NSF/ANSI standard 60-certified as a cleaner for potable water systems and manufactured in an ISO 9001 Certified Facility.